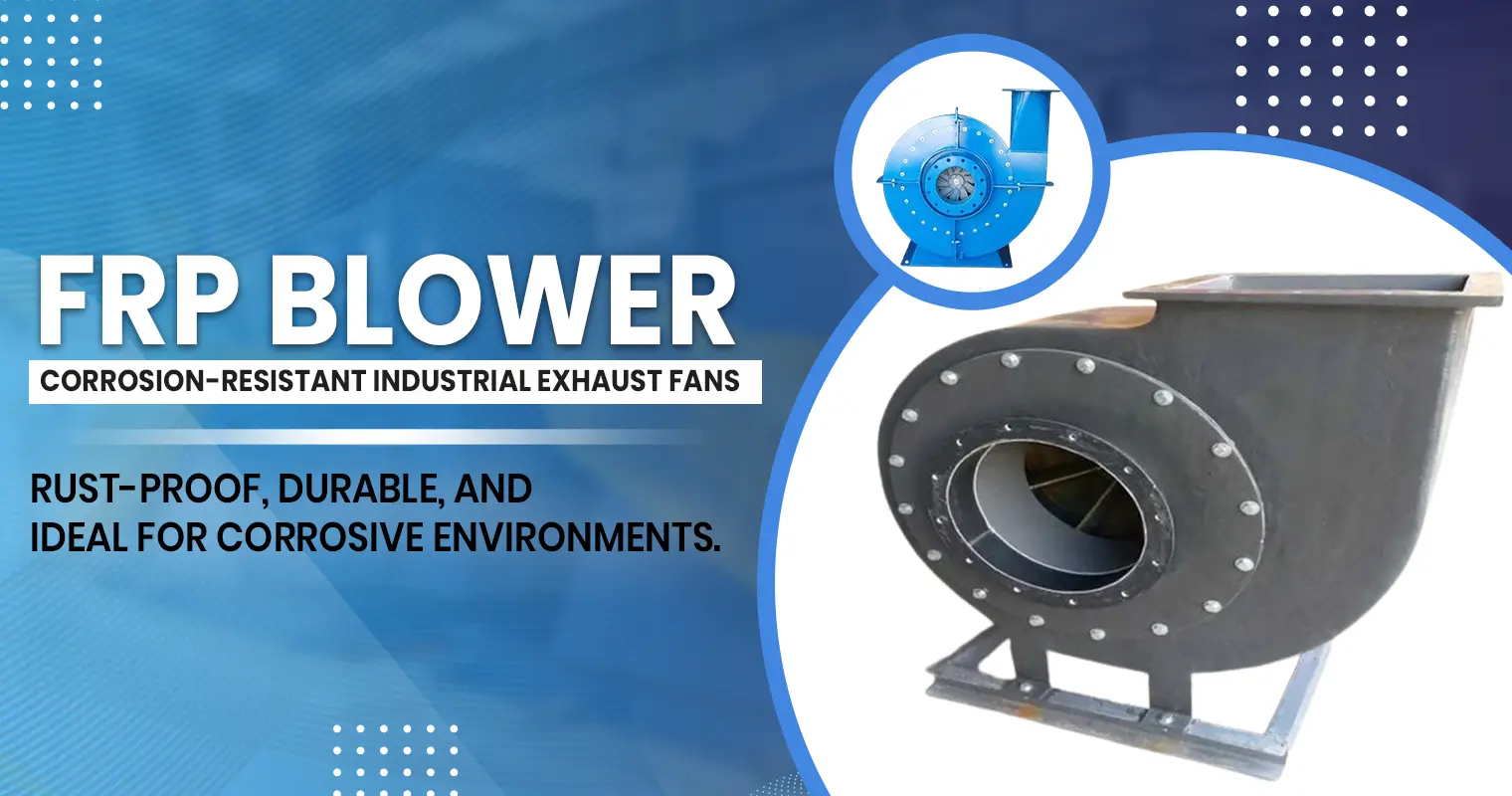

FRP Blower

FRP Blower

Our FRP blowers ensure corrosion resistance, smooth airflow, and low maintenance for fume extraction systems.

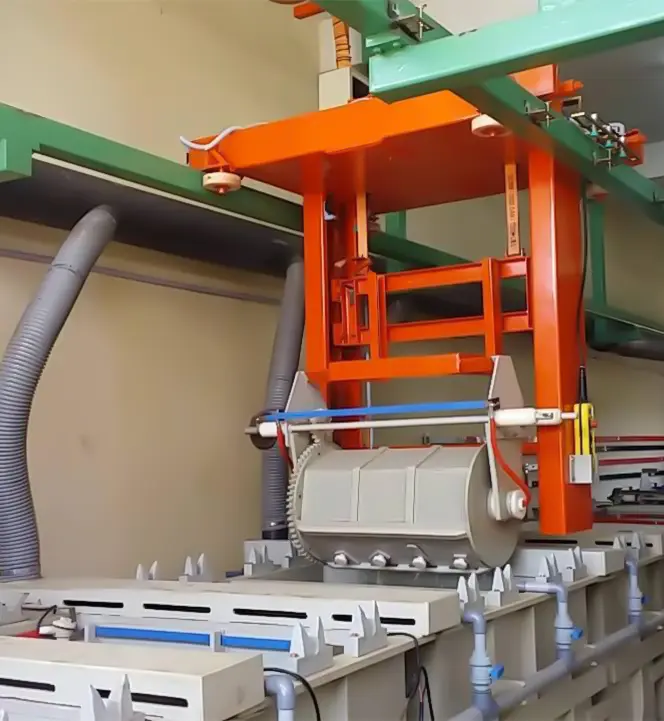

Zinc Plating Filter

Zinc Plating Filter

Ensure clean, particle-free zinc solutions with our high-performance filters built for durability and accuracy.

FRP Storage Tank

FRP Storage Tank

Ideal for storing corrosive chemicals, these tanks are leak-proof, weather-resistant, and customizable in size and shape.

Zinc Plating Barrels

Zinc Plating Barrels

Tough and reliable, these barrels handle high-volume electroplating jobs with ease and efficiency.

Alpha Engineering Works is your one stop solution for all your needs of FRP Blower Manufacturers in Maharashtra and hence we also work with plating chemicals suppliers, which allows us to tailor the compatibility of our equipment with typical zinc, copper, nickel, and gold solutions. Our filter products like the Zinc Plating Filter are stress-tested with a range of bath chemistries to ensure that they effectively strain out metal fines and residues without affecting bath performance. Such compatibility between equipment and chemistry is not a consideration for all manufacturers.

We are the top FRP Storage Tank Manufacturer in Nagpur. Regardless of the quantity of plants or 50 plating barrels the client needs, our machines can accommodate high-volume production with exact design consistency. All of the equipment is mapped and charted in the computer; not only do we produce quickly, but exact to the minute detail, too. Even in cases of emergency or rush supply requirements, our quality department works in tandem with our dispatch department to carry out individual inspections before packaging. This ensures zero defective or poorly constructed equipment delivery.

Choose us for all Best Zinc Plating Filter in India. We have a range of items that you can choose from- FRP Blower, Automatic Zinc Plating Barrels, FRP Storage Tank, FRP Fume Wet Scrubber, Zinc Plating Filter, Anodizing Plant, Air Agitation Blower, Zinc Plating Barrels, Gold Plating Plant. So what are you waiting for? The faster you place an order with us the faster we’ll deliver it in no time.

Our FRP Blowers, Air Agitation Blowers, and FRP Fume Wet Scrubbers are crafted for maximum efficiency, corrosion resistance, and minimal maintenance.

Whether it’s an Anodizing Plant or a Zinc Plating Filter, we tailor every system to match your specific production requirements and workflow.

We help you stay ahead of environmental norms with equipment that supports cleaner emissions and efficient chemical handling.

Understanding Your Requirement

Understanding Your Requirement

Every project starts with a detailed consultation. We listen to your operational challenges, space constraints, and plating or storage needs.

Design & Custom Engineeringz

Design & Custom Engineeringz

Based on your inputs, our expert team creates a custom design — whether it’s for a Zinc Plating Barrel, Anodizing Plant, or FRP Storage Tank.

Testing & Quality Checks

Testing & Quality Checks

Each unit undergoes rigorous testing for efficiency, leak-proof performance, corrosion resistance, and operational safety.

Delivery & Installation

Delivery & Installation

We ensure safe and on-time delivery to your site. Our team also provides guidance or assistance in setting up complex systems like plating plants and scrubbers.

We specialize in designing, manufacturing, and supplying high-quality equipment for the surface treatment and electroplating industry. Our solutions are engineered for durability, efficiency, and chemical resistance — making us a trusted name in the field.

Increase productivity with our automated barrels, designed for consistent plating quality and minimal operator intervention.

Engineered for efficient fume neutralization, our scrubbers help maintain a safe and compliant workspace.

Your satisfaction doesn’t end at delivery. We offer ongoing technical support and maintenance services to keep your equipment running smoothly.

Contact Number:

Mail Address:

Office Location:

Gajbhiye Layout, Plot 03, Ward No 02, Isasani Road Wagdara, Nagpur-441110, Maharashtra, India